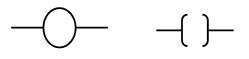

The magnetic contactor is similar in operation to the electromechanical relay (EMR).

The National Electrical Manufacturers Association (NEMA) difines a magnetic contactor as a magnetically actuated device for repeatedly establishing or interupting an electric power circuit.

The electromagnetically operated contactor is one of the most useful mechanisms ever devised for closing and opening electric circuits.

Contactors are used to switch power ON and OFF to a distribution panel.

They are also used with pilot devices to control the temperature and liquid level of a tank.

The advantages of using magnetic contactors instead of manually operated control equipment include the following :

- Where large currents or high voltages have to be handled, it is difficult to build a suitable manual apparatus. Furthermore, such an apparatusis large and hard to operate. On the other hand, it is a relatively simple matter to build a magnetic contactor that will handle large currents or high voltages, and the manual apparatus must control only the coil of the contactor.

- Contactors allow multiple operations to be performed from one operator (one location) and interlocked to prevent false and dangerous operations.

- Where the operation must be repeated many times an hour, a distinct saving in effort will result if contactors are used. The operator simply has to push a button and the contactors will automaically initiate the proper sequence of events.

- Contactors can be automatically controlled by very sensitive pilot devices. Pilot devices of this nature are limited in power and size, and it would be difficut to design them to handle heavy current directly.

- High voltage may be handled by the contactor and kept entirely away from the operator, thus increasing the safety of an installation. The operator also will not be in the proximity of high-power arcs, which are always a source of danger from shocks, burns, or perhaps injury the eyes.

- With contactors the cont rol equipment may be mounted at a remote point. The only space required near the machine will be the space needed for the pushbutton. It is possible to control one contactor from as many different pushbuttons as are desired, with only the necessity of running a few light control wires between the stations.

- Wirth contactors, automatic and semiautomatic control is possible with equipment such as programmable logic controllers (PLCs).